Metals in the Automotive Industry

Supplying Metal For Vehicle Manufacturing

Metal in the Automotive Industry

Colt Materials have been supplying metal to the Automotive industry for over a decade, with our range of steel, aluminium, and iron suited to the building of parts, vehicles, and machines that create components. Our products are all tested, and custom cut to your size requirements, making your projects easier, more cost-effective and seamless. For all your automotive part needs, our metals and their unique qualities will benefit your production. Aluminium, steel, and iron are the most commonly used metals, each selected based on specific mechanical, thermal, and environmental requirements.

The automotive industry relies heavily on metallic materials due to their strength, durability, manufacturability, and cost efficiency.

Metal Suppliers for the Automotive Industry

Aluminium in the Automotive Industry

Aluminium is increasingly used in modern vehicles as it's a low-density metal, made from one-third of steel. By reducing the vehicle mass, you’re improving the fuel efficiency and lowering emissions. Its low weight and high strength ratio make it well-suited to building vehicles like cars, vans and lorries. Aluminium has excellent corrosion resistance, which is ideal for vehicles as they spend lots of time in the rain and in hot and cold conditions. Its high thermal and electrical conductivity make it ideal for components in the engine and interior. Aluminium is widely recycled and is a sustainable product, so cars and their parts can be reused and the metal can have multiple lifespans.

Automotive applications

- Engine components: Aluminium alloys are widely used in engine blocks and cylinder heads. These components benefit from aluminium’s ability to dissipate heat efficiently, improving engine cooling and performance.

- Body panels and structures: Bonnet (hood), doors, roof panels, and tailgates are often made from aluminium to reduce overall vehicle weight while maintaining structural integrity.

- Chassis and suspension parts: Control arms, subframes, and cross members use aluminium to reduce unsprung mass, improving handling and ride comfort.

- Wheels: Aluminium alloy wheels provide weight reduction and improved aesthetics compared to steel wheels.

- Electric vehicle components: Battery enclosures, inverter housings, and motor casings commonly use aluminium for thermal management and corrosion resistance.

Steel in the Automotive Industry

Steel is a dominant material in this industry because vehicle manufacturing requires high strength, versatility and availability, with such a large range of vehicles always being made.

Mild steel: high ductility and malleability, weldable, low cost.

Automotive applications:

- Body-in-white components such as inner door panels, floor pans, and roof frames

- Non-structural brackets and mounts

- Outer body panels in economy vehicles

Stainless steel: superior corrosion resistance, high strength and long service life.

Automotive applications:

-

- Exhaust systems including pipes, mufflers, and tailpipes

- Catalytic converter housings

- Heat shields

- Decorative and protective trims

Tool Steel: With high hardness and strength maintained even at high temperatures. Tool steel is not typically used as a vehicle component, but it plays a crucial role in vehicle manufacturing.

Automotive applications:

- Stamping dies for forming steel body panels

- Moulds for plastic automotive components

Cutting and shaping tools used in engine and chassis production

Cast Iron in the Automotive Industry

Cast iron has been one of the most important engineering materials in the automotive industry for over a century. Despite the increasing use of aluminium and engineering plastics, cast iron remains essential in applications where high strength, wear resistance, thermal stability, and vibration damping are required.

Cast iron performs exceptionally well in high-friction environments, such as braking systems and engine cylinders, where resistance to wear is critical for long service life, as is heat resistance. It’s also well-suited to manufacturing vehicles because it offers good vibration and noise dampening.

Automotive applications

- Engine blocks, especially in diesel engines where high strength is required

- Brake discs (rotors) due to their ability to withstand high temperatures and friction

- Exhaust manifolds

- Cylinder liners

The Importance of Engineering Plastic in the Automotive Industry

Engineering plastics play a crucial role in the modern automotive industry due to their lightweight nature, design flexibility, durability, and cost efficiency. Replacing metal components with plastics significantly reduces overall vehicle weight, which leads to improved fuel economy in internal combustion engine vehicles and increased driving range in electric vehicles. Engineering plastics can be easily moulded into complex shapes, allowing manufacturers to integrate multiple functions into a single component. This reduces the number of parts, assembly time, and manufacturing costs.

Explore the plastic we stock at Colt Materials and enquire for a free quotation today.

Why Choose Colt Materials for Your Metals in the Automotive Industry?

Choosing the right metal supplier is essential to ensuring the strength, durability, and efficiency of any construction project. We stand out as a trusted supplier in the industry because we deliver more than materials; we deliver reliability, quality, and expertise.

We source only high-quality aluminium, stainless steel, and cast iron that meet strict industry standards. Whether their needs are in the body parts, engine, tools for manufacturing or small components, our products deliver high-quality results.

Construction | Aerospace | Engineering | Defence | Automotive | Healthcare |

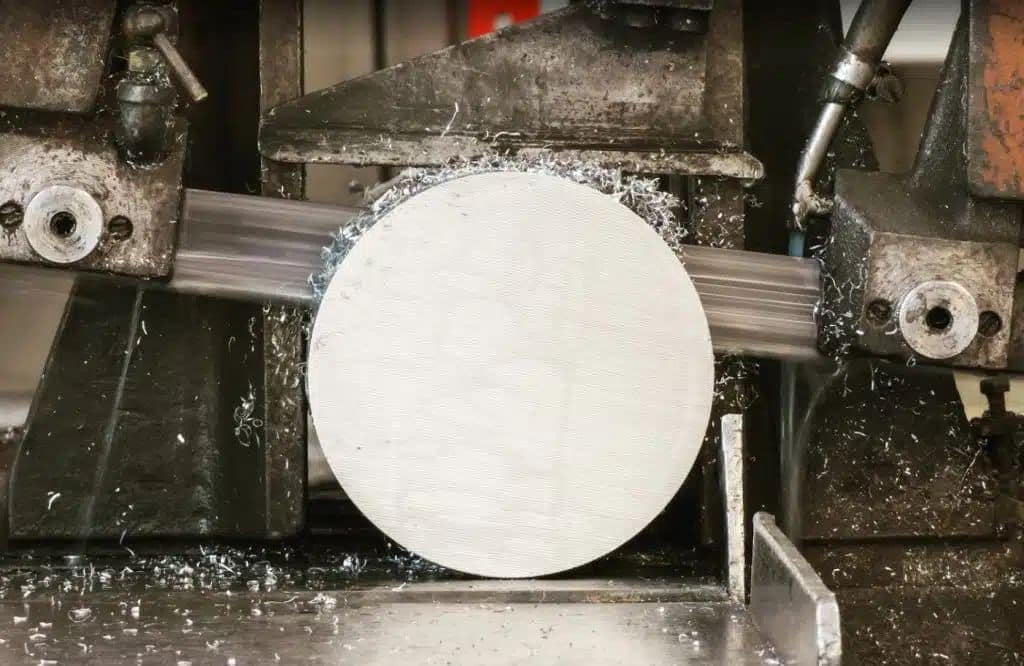

Our Bespoke Metal Cutting Service

Our metal cutting service is designed to provide precision, efficiency, and convenience for customers who require materials tailored to their exact specifications. Using advanced cutting technology, we deliver clean, accurate cuts on a wide range of metals, reducing waste and saving valuable time in the fabrication process. Whether you need custom sizes for construction, manufacturing, or specialised projects, our skilled team ensures every order meets the highest standards of quality.

Enquire today with measurements to place your order.