Aluminium

Aluminium Supplier of: 6082, 5083, 2014 & 2011

Aluminium 6082

Aluminium 6082 is a medium-strength, heat-treatable alloy in the 6000 series, primarily alloyed with magnesium, silicon, and small amounts of manganese. It offers excellent strength, corrosion resistance, and good machinability and weldability. With the highest strength in the 6000 series, 6082 is ideal for structural applications such as bridges, cranes, and marine equipment. It is also widely used in the automotive and aerospace industries for components that require a strong yet lightweight material. Its good corrosion resistance makes it suitable for outdoor and marine environments, while its machinability and weldability ensure ease of fabrication.

Aluminium 5083

Grade 5083 aluminium is a non-heat treatable alloy that is alloyed with magnesium, manganese, and chromium, which significantly improves its performance in demanding environments. This combination of elements gives it exceptional resistance to corrosion, particularly in seawater and industrial chemical settings, making it ideal for marine and chemical processing applications.

Alloy 5083 is commonly used in plate form, and it's highly valued for its strength and durability, especially in the construction of ships, offshore structures, and tanks. One of its key advantages is that it retains its high strength even after welding, which is a challenge for many other aluminium alloys. As a result, it is the strongest of the non-heat treatable aluminium alloys, providing reliable performance in critical, high-stress applications.

Grade 5083 offers good formability and is often used in industries where materials are exposed to extreme weather conditions or aggressive chemicals. Its combination of strength, corrosion resistance, and workability makes it a preferred choice for marine, transportation, and industrial applications.

Aluminium 2014

Grade 2014A aluminium is a high-performance alloy known for its exceptional strength-to-weight ratio and heat treatability. This alloy is primarily composed of aluminium, with a significant addition of 4-5% copper. This copper content plays a crucial role in enhancing the alloy's mechanical properties, particularly its strength and hardness.

2014A aluminium is typically produced in the form of bars and profiles. To achieve optimal performance, it is fully heat-treated during the manufacturing process. This heat treatment involves a series of controlled heating and cooling cycles that refine the alloy's microstructure, resulting in significant improvements in strength, ductility, and toughness.

Due to its outstanding strength-to-weight ratio, 2014A aluminium is widely used in industries that demand lightweight, high-strength materials. It is particularly popular in the aerospace and defence sectors, where it is employed in the construction of critical components such as aircraft structures, landing gear, and truck frames. Its ability to withstand high loads and harsh environmental conditions makes it an ideal choice for these demanding applications.

Aluminium 2011

Alloy 2011, often referred to as a Free-Machining Alloy (FMA), is renowned for its exceptional machinability. This characteristic makes it highly suitable for automated lathe operations, enabling the efficient production of intricate and detailed components.

However, 2011 aluminium exhibits poor corrosion resistance. To mitigate this limitation and provide additional surface protection, anodising is commonly employed. This electrochemical process forms a hard, protective oxide layer on the aluminium surface, enhancing its resistance to corrosion and wear.

While the weldability of 2011 aluminium is limited, its excellent machinability compensates for this drawback. This alloy's versatility allows for the creation of a wide range of complex components, making it a valuable material in various industries.

Colt Materials are your local aluminium stockholders Call us today!

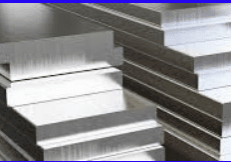

Aluminium Tooling Plate

The C250 precision plate, meticulously machined on both sides, is crafted from the versatile EN AW-5083 (AlMg4.5Mn0.7) alloy. This alloy's wide range of applications is well-established.

The production process involves rolling ingots, which are carefully manufactured to achieve a fine-grained, homogeneous structure. This is accomplished through a modified casting process and specific heat treatments, minimising micro porosity.

The resulting precision plates exhibit exceptional uniformity in flatness, coupled with high strength and excellent technical anodizing properties. These characteristics make the C250 precision plate a reliable and durable material for a wide range of applications, particularly those requiring precise dimensions and superior surface quality.

FAQS on Aluminium

Aluminium shines as a good conductor of electricity. This stems from its abundant free-flowing electrons within the atomic structure. This property makes aluminium a popular choice for applications like electrical transmission lines, where efficient current flow is crucial.

Aluminium reigns supreme as the better electrical conductor compared to steel. This is because aluminium has more freely moving electrons within its atomic structure, allowing electricity to flow more efficiently.

Aluminium reigns as the third most common element in Earth's crust, constituting roughly 8% of its soil and rocks. Only oxygen and silicon hold higher abundances. Bauxites is the most common raw material in aluminium production. They are mainly made up of aluminium oxide mixed with some other minerals.

Several welding processes work well for aluminium, including TIG (GTAW), MIG (GMAW), and laser beam welding. Unlike steel, aluminium requires specific techniques due to its properties like:

High thermal conductivity: Aluminium heats up quickly and disperses heat efficiently, making it trickier to maintain a molten weld pool.

Oxidation: Aluminium forms a thin oxide layer that hinders a strong weld. Welders need to remove this oxide layer for proper fusion.

Aluminium's impressive strength-to-weight ratio makes it ideal for situations where weight reduction is crucial. This is why it's widely used in: Transportation, construction, power lines, electrical appliances, drinking cans, outdoor applications, consumer goods, aerospace parts and more...