Tufnol Plastic

What is TUFNOL?

TUFNOL is a branded laminated plastic material that has been manufactured in Birmingham, England since the mid-1920s. It stands as one of the pioneering resin-bonded plastic materials utilised in engineering components.

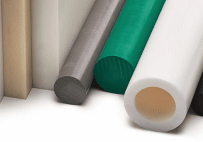

While many individuals are familiar with laminates as thin, hard sheets used in applications such as kitchen worktops and flooring (termed 'decorative laminates'), TUFNOL falls under the category of 'industrial laminates'. Unlike decorative laminates, TUFNOL lacks a specially coloured or patterned surface layer. Instead, it is produced in large blocks as well as thin sheets, primarily utilised in the creation of machinery components and for industrial purposes. Typically, it exhibits colours ranging from brown to white, depending on the grade, and can be manufactured in solid sheets up to 225mm (9 inches) thick, as well as in round rods and tubes.

Why use Tufnol?

- Mechanical Strength: TUFNOL offers excellent mechanical properties, including high strength, stiffness, and impact resistance, making it suitable for use in components subject to heavy loads and mechanical stresses.

- Electrical Insulation: It possesses excellent electrical insulation properties, making it ideal for use in electrical and electronic applications where insulation is crucial to prevent electrical conductivity or short circuits.

- Chemical Resistance: TUFNOL is resistant to a wide range of chemicals, including acids, alkalis, solvents, and oils, making it suitable for use in environments where exposure to such substances is common.

- Dimensional Stability: It exhibits good dimensional stability over a wide range of temperatures, ensuring that components made from TUFNOL maintain their shape and size even under varying environmental conditions.

- Machinability: TUFNOL is relatively easy to machine using standard machining techniques, allowing for the production of complex shapes and components with tight tolerances.

- Cost-Effectiveness: It offers a cost-effective alternative to metal and other materials in many applications, providing comparable performance at a lower cost.

- Corrosion Resistance: TUFNOL is resistant to corrosion, making it suitable for use in environments where exposure to moisture or corrosive substances is a concern.