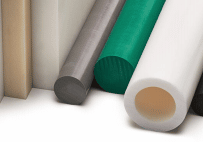

Polyether Ether Ketone

WHAT IS PEEK?

Polyether ether ketone (PEEK) is a colourless organic thermoplastic polymer belonging to the polyaryletherketone (PAEK) family, utilized in various engineering applications.

PEEK is a semicrystalline thermoplastic known for its outstanding mechanical and chemical resistance properties, which are maintained even at high temperatures. The moulding conditions for PEEK can affect its crystallinity and, consequently, its mechanical characteristics. It has a Young's modulus of 3.6 GPa and a tensile strength ranging from 90 to 100 MPa. PEEK exhibits a glass transition temperature of approximately 143°C (289°F) and a melting point around 343°C (662°F). Certain grades can function at temperatures up to 250°C (482°F). PEEK is highly resistant to thermal degradation and can withstand attacks from both organic and aqueous environments. However, it is susceptible to halogens, strong acids, and some halogenated compounds and aliphatic hydrocarbons at elevated temperatures. It fully dissolves in concentrated sulfuric acid at room temperature.

Due to its durability, PEEK is employed in the production of components used in rigorous applications, such as bearings, piston parts, pumps, HPLC columns, compressor plate valves, and cable insulation. It is one of the few plastics suitable for ultra-high vacuum environments and is widely used in the aerospace, automotive, and chemical processing industries.

Beneficial Properties

Polyether ether ketone (PEEK) possesses several beneficial properties that make it highly valuable in various engineering applications. Some of its key beneficial properties include:

- Good dimensional stability

- Superior Chemical resistance

- Superior wear & friction resistance

- High mechanical strength

- Superior resistance to gamma and X-rays

- High vacuum applications

Applications

Polyether ether ketone (PEEK) is utilized in a wide range of applications across various industries due to its exceptional properties. Some of the key applications include:

- Nuclear environments

- Oil & Geothermal wells

- Chemical industries

- High-pressure valves

- Food processing equipment

- High Vacuum plant

Below are the Industries that utilise this material:

Aerospace:

- Bearings and Bushings: High wear resistance and stability in harsh environments.

- Structural Components: Lightweight yet strong components for aircraft and spacecraft.

- Insulating Components: Electrical insulation for wiring and components.

Automotive:

- Engine Components: Piston parts, seals, and gaskets that withstand high temperatures and mechanical stress.

- Transmission Components: Gears and other transmission parts that require high wear resistance and durability.

- Electrical Connectors: Insulators and connectors due to its excellent electrical properties.

Medical:

- Surgical Instruments: Tools that require high sterilization resistance.

- Implants: Biocompatible components such as spinal implants and dental devices.

- Orthopedic Devices: Joint replacements and other prosthetics.

Industrial:

- Pumps and Valves: Components that handle aggressive chemicals and high temperatures.

- HPLC Columns: High-performance liquid chromatography columns for chemical analysis.

- Compressor Plate Valves: Durable parts that maintain performance under stress.

Electronics:

- Semiconductor Manufacturing: Parts used in fabrication equipment that must endure high temperatures and chemical exposure.

- Cable Insulation: Insulating materials for high-performance electrical cables.

- Connectors and Switches: Precision components requiring stability and reliability.

Chemical Processing:

- Chemical Resistance Components: Pipes, fittings, and containers that handle corrosive substances.

- Seals and Gaskets: High-performance seals for pumps and reactors.

Energy:

- Oil and Gas: Components used in downhole and subsea environments where high temperatures and chemical resistance are crucial.

- Renewable Energy: Parts in solar panels and wind turbines that must withstand harsh environmental conditions.

Food and Beverage:

- Processing Equipment: Machinery components that require high hygiene standards and resistance to cleaning chemicals.